Instrument Stainless Steel Connector Tube Fitting

Product Description

Material: Stainless Steel Head Type: Round Specification: 1/16 in. to 2 in. HS Code: 730729000 Connection: Male Trademark: J&O Origin: Wenzhou, China J&O FLUID CONTROL CO., LIMITED

Reliable J&O® Brand ®

Over 10 years Exporting Experiences

ISO9001,3A, FDA Certification

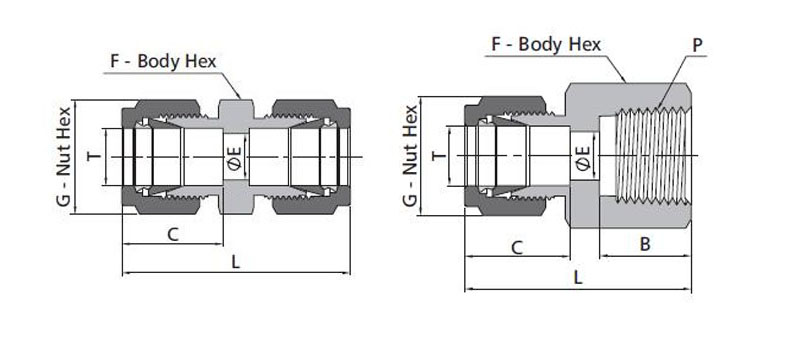

Instrument Stainless Steel Connector Tube Fitting Product Features 1. Twin ferrule fittings provide metal-to-metal seal connections, non-elastomeric seals for leak-free connections.

2. Twin ferrule fittings is designed to have a maximum allowable working pressure that is higher than that of any tubing.

3. Stainless steel tube harderness: the hardness of the tube shall be not greater than 85 HRB.

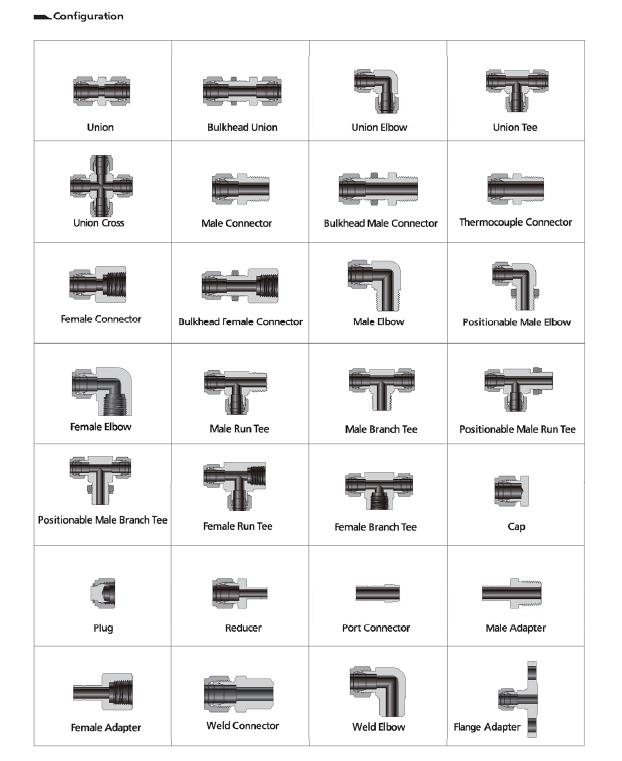

4. Available in sizes from 1/16 to 2in and 2 mm to 50 mm.

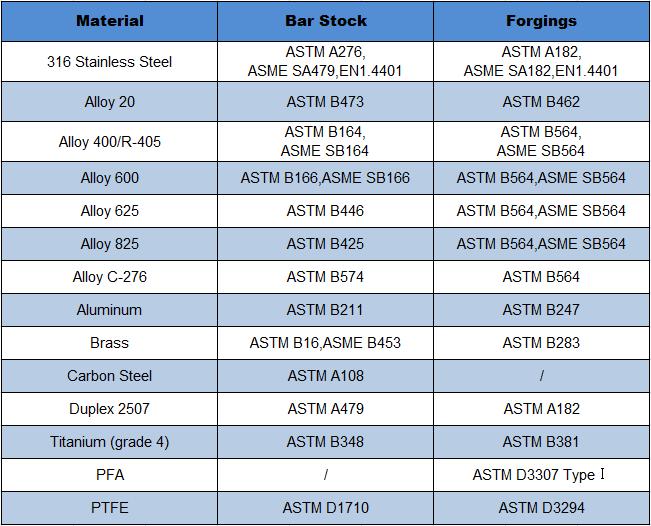

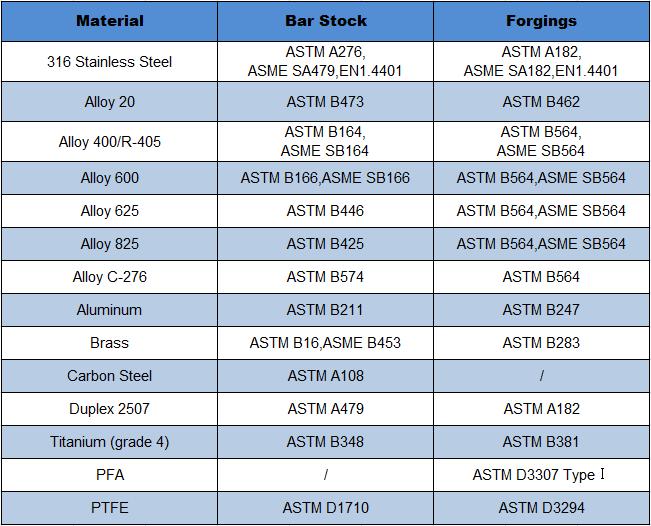

5. Fittings materials include 316 stainless steel, steel, brass, aluminum, nickel-copper, Hastelloy C, 6Mo, Incoloy 625 and 825.

6. Special treated Back ferrule is to provide secure.

7. Silver coated threads to reduce galling.

8. Leak-proof joints capable of satisfying high pressure vacuum and vibration applications.

9. Industry standard design for all instrumentation grade tubing. Product Performance 1. Hydraulic proof pressure test (1.5 times the maximum permissible working pressure): no leakage.

2. Dismantling and reassembly test (dismantle ten times): no leakage.

3. Vacuum test (1 × 10−4 mbar or greater): the leak rate less than 1 × 10−8.

4. Maximum static gas pressure test (with nitrogen gas to 150% of pressure rating): no visible bubbles.

5. Hydraulic impulse and vibration test (the pressure impulses at between 0.5 Hz and 1.7 Hz and the vibration at between 23 Hz and 47 Hz): no leakage.

6. Thermal cycle test (ambient to +80 °C and then to -25 °C with a hydrostatic pressure): no evidence of leakage.

7.Pneumatic pressure vibration test (The frequency of vibration shall be set at 45 Hz and complete 20 × 106 cycles): without failure

8. Fire test (in accordance with BS ISO 19921): no leakage.

9. Corrosion resistance test (the duration of exposure at least 168 h): no visible evidence of corrosion.

10. Deep water submersion test (equivalent to 3048 m of sea water): no helium detected.

11. Minimum hydrostatic pressure test (four times the maximum permissible ambient pressure rating): no leakage.

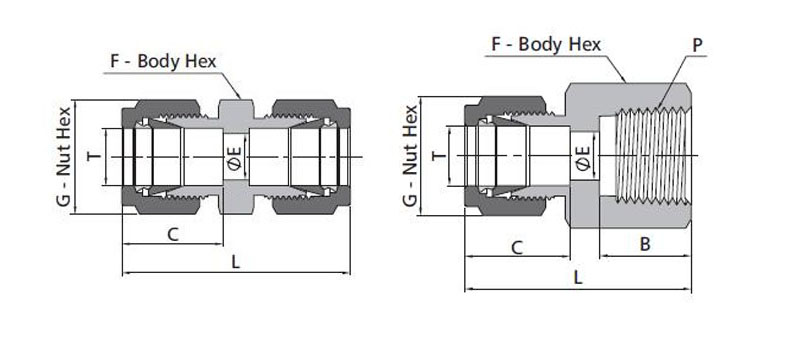

Thread Specification

Pressure Ratings

We can supply:

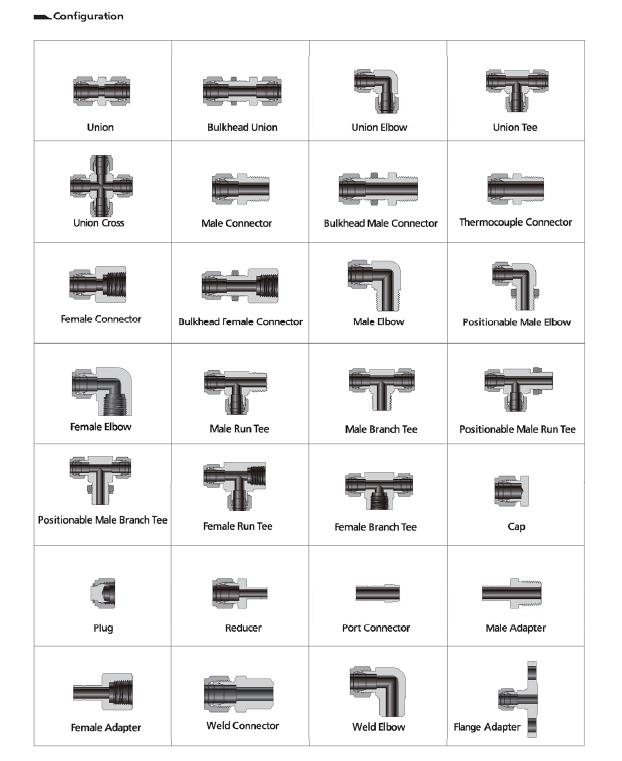

J&O valves including Sanitary butterfly valve, Sanitary Ball Valve, Mixing Proof Valve, Divert Valve, Check Valve and Diaphragm Valves, as well as Various Tank Accessories: Sampling Valve, Safety valve, Relief Valve, Manhole Way, Sight Glass , Strainers/Filter, Cleaning Ball, And other Pipe Fittings, (Pipe Unions: SMS, DIN, IDF, RJT,3A; Fittings: Elbow, Tee, Reducer), each products are tested well by our strictly Quality Control System, and we also have excellent service to support you and promote your business.

Lead Time:

For large quantity, as usual, it can be sent out within 20-40 days.

Small parcel will be dispatched by DHL, FEDEX, UPS OR TNT Courier.

Big cargo will be delivered by Air freight or By Sea.

Our Service:

About payment:

Payment methods: L/C, T/ T, Western Union

About samples:

We can provide samples production and service. Usually 2 to 5 days, the sample can be sent to your hands. We will choose the shipping way as you required: by sea, by air or by express. Any question about samples, please contact us.

For OEM products:

We will finish the production within 20-40 days after payment has been confirmed.

About delivery and shipping:

We will choose the delivery way as you required: by sea, by air, by express ect. Save your cost is our mission.

Warranty:

Any question or problem will be respond within 24 hours.

Lifetime service:

Any problem happened to our product, we will do our best to help client to solve it, spare parts will be half price in lifetime.

Problem solve:

If you can't solve the problem in your local, please delivery the product to us, we will repair it and then back to you.

Quality control:

All the products are calibrated with real working condition, and tested before shipping as qualified product.

Integrity: All the warranty and guarantee from us will be put into come true

Contact us if you need more details on Stainless Steel Tube Fitting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stainless Steel Connector、Stainless Steel Pipe Fitting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Reliable J&O® Brand ®

Over 10 years Exporting Experiences

ISO9001,3A, FDA Certification

Instrument Stainless Steel Connector Tube Fitting Product Features 1. Twin ferrule fittings provide metal-to-metal seal connections, non-elastomeric seals for leak-free connections.

2. Twin ferrule fittings is designed to have a maximum allowable working pressure that is higher than that of any tubing.

3. Stainless steel tube harderness: the hardness of the tube shall be not greater than 85 HRB.

4. Available in sizes from 1/16 to 2in and 2 mm to 50 mm.

5. Fittings materials include 316 stainless steel, steel, brass, aluminum, nickel-copper, Hastelloy C, 6Mo, Incoloy 625 and 825.

6. Special treated Back ferrule is to provide secure.

7. Silver coated threads to reduce galling.

8. Leak-proof joints capable of satisfying high pressure vacuum and vibration applications.

9. Industry standard design for all instrumentation grade tubing. Product Performance 1. Hydraulic proof pressure test (1.5 times the maximum permissible working pressure): no leakage.

2. Dismantling and reassembly test (dismantle ten times): no leakage.

3. Vacuum test (1 × 10−4 mbar or greater): the leak rate less than 1 × 10−8.

4. Maximum static gas pressure test (with nitrogen gas to 150% of pressure rating): no visible bubbles.

5. Hydraulic impulse and vibration test (the pressure impulses at between 0.5 Hz and 1.7 Hz and the vibration at between 23 Hz and 47 Hz): no leakage.

6. Thermal cycle test (ambient to +80 °C and then to -25 °C with a hydrostatic pressure): no evidence of leakage.

7.Pneumatic pressure vibration test (The frequency of vibration shall be set at 45 Hz and complete 20 × 106 cycles): without failure

8. Fire test (in accordance with BS ISO 19921): no leakage.

9. Corrosion resistance test (the duration of exposure at least 168 h): no visible evidence of corrosion.

10. Deep water submersion test (equivalent to 3048 m of sea water): no helium detected.

11. Minimum hydrostatic pressure test (four times the maximum permissible ambient pressure rating): no leakage.

Thread Specification

| Thread Type(End Connection) | Reference Specification | |||||||

| NPT | ASME B1.20.1 SAE AS71051 | |||||||

| ISO/BSP(paralld)(Based on DIN 3852) | ISO 228.JIS B0202 | |||||||

| ISO/BSP(Tapered)(Based on DIN 3852) | ISO 7.BS EN 10226-1,JIS B0203 | |||||||

| ISO/BSP(gauge)(Based on EN 837-1 and 837-3) | ISO 228.JIS B0202 | |||||||

| Unified(SAE) | ASME B1.1 | |||||||

| NPT/ISO Pipe Size | 316 SS And Carbon Steel | Brass | ||||||

| Male | Female | Male | Female | |||||

| Psig | bar | Psig | bar | Psig | bar | Psig | bar | |

| 1/16 | 11000 | 760 | 6700 | 460 | 5500 | 380 | 3300 | 230 |

| 1/8 | 10000 | 690 | 6500 | 440 | 5000 | 340 | 3200 | 220 |

| 1/4 | 8000 | 550 | 6600 | 450 | 4000 | 270 | 3300 | 220 |

| 3/8 | 7800 | 540 | 5300 | 360 | 3900 | 270 | 2600 | 180 |

| 1/2 | 7700 | 530 | 4900 | 330 | 3800 | 260 | 2400 | 160 |

| 3/4 | 7300 | 500 | 4600 | 320 | 3600 | 250 | 2300 | 160 |

| 1 | 5300 | 370 | 4400 | 300 | 2600 | 180 | 2200 | 150 |

| 1 1/4 | 6000 | 410 | 5000 | 350 | 3000 | 200 | 2500 | 170 |

| 1 1/2 | 5000 | 340 | 4600 | 310 | 2500 | 170 | 2300 | 150 |

| 2 | 3900 | 270 | 3900 | 270 | 1900 | 130 | 1900 | 130 |

We can supply:

J&O valves including Sanitary butterfly valve, Sanitary Ball Valve, Mixing Proof Valve, Divert Valve, Check Valve and Diaphragm Valves, as well as Various Tank Accessories: Sampling Valve, Safety valve, Relief Valve, Manhole Way, Sight Glass , Strainers/Filter, Cleaning Ball, And other Pipe Fittings, (Pipe Unions: SMS, DIN, IDF, RJT,3A; Fittings: Elbow, Tee, Reducer), each products are tested well by our strictly Quality Control System, and we also have excellent service to support you and promote your business.

Lead Time:

For large quantity, as usual, it can be sent out within 20-40 days.

Small parcel will be dispatched by DHL, FEDEX, UPS OR TNT Courier.

Big cargo will be delivered by Air freight or By Sea.

Our Service:

About payment:

Payment methods: L/C, T/ T, Western Union

About samples:

We can provide samples production and service. Usually 2 to 5 days, the sample can be sent to your hands. We will choose the shipping way as you required: by sea, by air or by express. Any question about samples, please contact us.

For OEM products:

We will finish the production within 20-40 days after payment has been confirmed.

About delivery and shipping:

We will choose the delivery way as you required: by sea, by air, by express ect. Save your cost is our mission.

Warranty:

Any question or problem will be respond within 24 hours.

Lifetime service:

Any problem happened to our product, we will do our best to help client to solve it, spare parts will be half price in lifetime.

Problem solve:

If you can't solve the problem in your local, please delivery the product to us, we will repair it and then back to you.

Quality control:

All the products are calibrated with real working condition, and tested before shipping as qualified product.

Integrity: All the warranty and guarantee from us will be put into come true

Contact us if you need more details on Stainless Steel Tube Fitting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stainless Steel Connector、Stainless Steel Pipe Fitting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Instrumentation Valves and Fittings > Double Ferrule Tube Fittings

Premium Related Products

Other Products

Hot Products

High pressure natural gas instrument air manifoldStainless steel industrial 3-way valve manifoldFloat angle double block and bleed plug valve3 way lockable forged ball valvestainless steel three way port ball valveThreaded stainless steel cross ball valvesStainless high pressure air precision needle valveTube compression fittings angle air operate needle valvecf8m stainless steel female male automatic ball valve.JW-LOK Hamlet instrument ball valveStainless steel multi port gauge valveHigh pressure 2 way valve manifoldHigh pressure 6000psig bar stock ball valveSpeedy Trunnion Mounted Ball Valve for natural gasMost selling products of radiator auto air vent valveHigh quality Forged steel piston globe valve