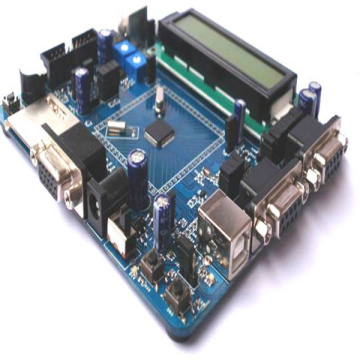

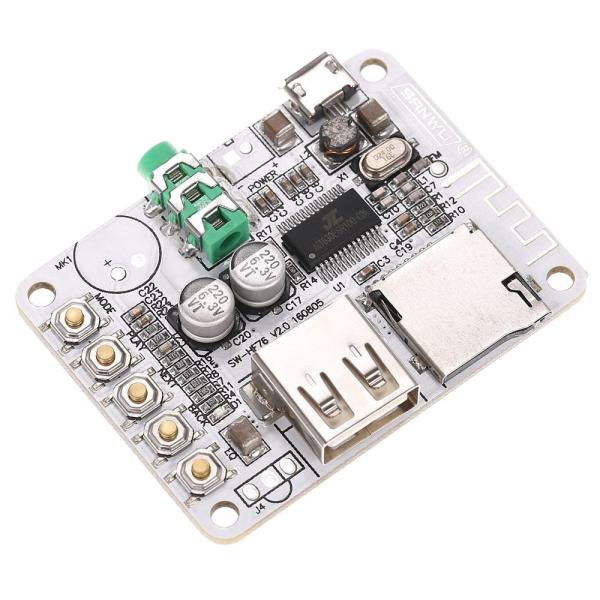

Air Flow Meter PCB Assembly

Basic Info

Model No.: Air Flow Meter PCB

Product Description

How is PCB designed?

PCB layout design:

1.1 Preparations before layout:

1) Check whether the capture point setting is correct. 08 process is 0.1, 06 process is 0.05, 05 process is 0.025.2. Cell name cannot start with a number. Otherwise, DRACULA check cannot be done.

2) Consider the direction and location of the PIN before layout

3) Analyze the circuit before layout, and draw the MOS tubes of the same function together

4) Pre-order the direction of the two layers of metal. The direction of the grid in a picture should be as consistent as possible, not horizontal and vertical.

1.2 Layout principles

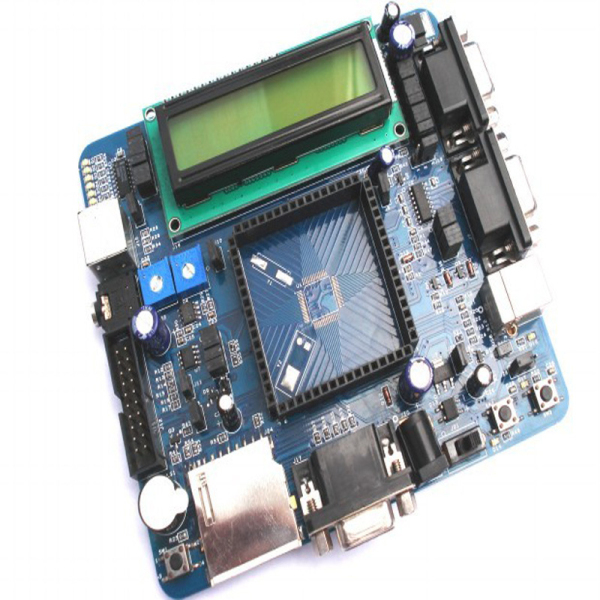

1.3 Component arrangement rules

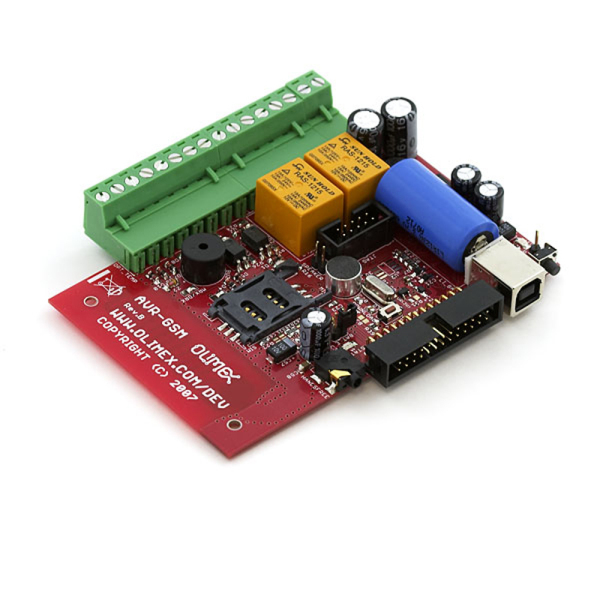

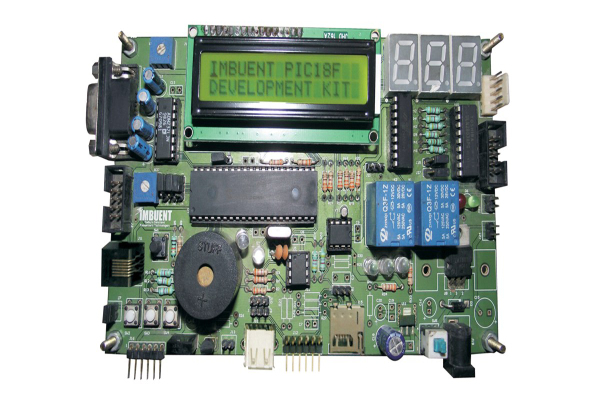

1). Under normal conditions, all Electronic Components should be arranged on the same side of the printed circuit. Only when the top Electronic Components are too dense can some devices with limited height and low heat generation, such as chip resistors, Chip capacitors and ICs are placed on the bottom layer.

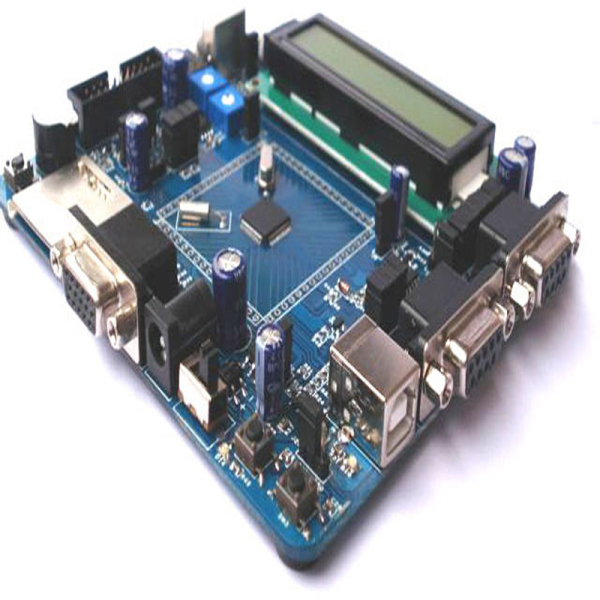

2). On the premise of ensuring electrical performance, Electronic Components should be placed on the grid and arranged in parallel or perpendicular to each other in order to be neat and beautiful. Generally, no overlapping of components is allowed; the arrangement of components should be compact, and input and output components should be as close as possible. keep away.

3). Certain components or Cable Connectors I/O Connectors may have a higher potential difference, and the distance between them should be increased to avoid accidental short circuits caused by discharge and breakdown.

4). Components with high voltage should be arranged as far as possible in places that are not easily reachable by hands during debugging.

5). Components located at the edge of the board should be at least 2 board thickness away from the edge of the board

6). The components should be distributed evenly and densely on the entire board to facilitate Surface-Mount (SMT) &BGA Assembly.

2.High frequency board according to the signal direction layout principle

3. Prevent electromagnetic interference

4. Suppress heat and dry winding. Try to use metal base printed board.

5. The layout of adjustable components is convenient for PCBA Manufacturing.

For the layout of adjustable components such as potentiometers, variable capacitors, adjustable inductors or micro switches, the structural requirements of the whole machine should be considered. If it is adjusted outside the machine, its position should be the same as the position of the adjustment knob on the chassis panel.

Adaptable; if it is adjusted inside the machine, it should be placed on the printed circuit board where it is adjusted.

.

Product Categories : PCB Assembly Products > Turkey PCB Assembly