Mass Flow +Volume Flow+Density +Temperature Indicator Mass Flowmeter

Basic Info

Model No.: CMF

Product Description

Model NO.: CMF Main Application: Water, Wastewater, Diesel Fuel, Fuel Oil, Nature Gas, Corrosive Liquid/Gas Sensor: Clamp-on/External Type: Coriolis Mass Flow Meter Measuring Principle: Thermodynamic Certification: JIS, DIN, ANS, GB, CE, UL, SGS, ISO Output Signal: 4-20mA, Pulse, RS485, Hart Fluid Types: Two-Phase Flow, Three-Phase Flow Indicator: Density+Mass/Volume Flow+Viscosity+Pressure+Temp. Trademark: U-ideal Origin: Tianjin, China Accuracy: ≤±0.1% Size: Dn1.5~Dn200 Application: Energy Metering Measuring Media: Liquid Measurement Object: Closed Pipeline Flow Fluid Measured: Liquid, Air, Solid Flow Indicate: Flow Rate, Total Flow, Density, Temperature Connection: Tube/Flange, Plug-in, Clamp, Snap Explosion-Proof: Intrinsic Safety, Ex-Proof CT6 Specification: Hart IP67 HS Code: 90261000 mass flow transmitter - Coriolis Mass Flow Meters

Mass flow+ volume flow+density +temperature measurement+calculated variables (e.g. fluid concentrations)

I. Main technical parameters

(1) Measurement scope: 2kg/h~500t/h

(2) Accuracy: ± 0.2%~± 0.15%

(3) Work pressure: (0~32) MPa (in case of other high pressure, it must be of special order)

(4) Medium temperature: -50º C~ +350º C,

Measurement accuracy: ± 1º C

(5) Environment temperature: -20º C ~ +70º C

(6) Measurement medium: Liquid, gas, solid, or two phases and three phases mixed fluid

(7) Output signal:

4-20mA current signal of flow, with load resistance ≤ 500Ω

0-10kHz frequency signal of flow.

RS485 Communication protocol

Hart protocol

(8) Power supply voltage: 24VDC

(9) Measurement of measuring pipe: 316L stainless steel

(10) Response time: 0.1s~5s, adjustable

(11) Explosion-proof grade: Ex(ib)II BT2-T5

Mass flow sensor

Composite type mass flowmeter- all - in- one type

Structure:

Every meter consists of two parts: the sensor (primary meter) and the transmitter (secondary meter). The sensor (primary meter) is machinery part of mass flow meter. There are a vibrator, two displacement sensors and a temperature sensor in it.

The transmitter (secondary meter) is display part of the meter, also is electrical part. There are power supply, analog circuits, digital circuits, displayer, and output circuits and so on in it. Its foundational functions are receiving and regulating the electrical signal from sensors, directly getting mass flow, temperature and density after regulating, and calculating volume flow and other need parameters from known parameters. It can display, output, store and long distance transmit, and you can modify the parameters of Flow Meter. There is a diode safety barrier in transmitters; the function of the diode safety barrier is safeguard to isolating explosion.

As the composite explosion-proof flow meter, the sensor (primary meter) is essential safety; the transmitter (secondary meter) is explosion isolated. The sensor and the transmitter may all operate under hazardous area.

As the essential safety flow meter, the sensor (primary meter) can operate under hazardous area, the transmitter (secondary meter) must only operate under prescriptive safety area (see section 3.2), forbidden to operate under hazardous area.

The sensor can be installed vertically or horizontally.

1. Introduction of Coriolis flow meter

The Coriolis force mass flowmeter can measure the mass flow rate directly, and won't be affected by the measured medium temperature, pressure, density, viscosity.

High precision of CMF series of Coriolis force mass flowmeter is mainly used to measure the instantaneous mass flow rate and cumulative mass flow, instantaneous volume flow and cumulative volume flow, at the same time also can display the medium temperature, medium density or concentration. It is mainly suitable for the following industries:

(1) he Toil industry, such as diesel, gasoline, heavy oil fuel metering; Crude oil output measurement, moisture content, the single well production; Crude oil loading and unloading metering, etc.;

(2) The chemical industry, such as toluene, xylene, butanone, cyclohexanone, n-butyl alcohol, isobutyl alcohol, methylene chloride, chloroform, liquid sulfur, lactam etc;

(3) The power industry, such as heavy oil, diesel fuel oil metering, slurry density meter limestone-gypsum wet desulphurization;

(4) The food, pharmaceutical industries, such as chocolate syrup, milk, fruit juice, pharmaceuticals, BPC (bulk pharmaceutical chemicals) measurement (clamp type healthy connection type);

(5) The energy industry, such as liquefied petroleum gas, natural gas, high pressure gas metering;

Introduction Coriolis Mass Flow Meters patented and developed by our company are the leading meters for precision flow measurement. And with good reason, the meters offer the most accurate measurement available for virtually any process fluid, while exhibiting exceptionally low pressure drop. The meters offer direct mass flow, volume flow, density, and temperature measurement of liquids and slurries - without the need for additional equipment, manual calculations, or estimations.

The meters are designed for unsurpassed performance in even the harshest operating environments. They have no moving parts, and any special mounting or flow conditioning requirements. Every meter is available with stainless steel wetted parts and a wide variety of process connections to meet your every need.

The meters carry hazardous area approval for P. R. China.

1. Principles of Measurement

The structure of Coriolis Mass Flow Meters was consisted of a pair of bended tubes. The principle is to detect Coriolis force forced a pair of tubes from inner mass flow by fluid.

A new force-Coriolis force would be appear while two conditions met: (1) vibrating with normal frequency in a pair of bended tubes, (2) fluid flowing in tubes. This force was produced upon synthesis from vibrating force and flowing force by fluid in tubes. And tubes would be wresting symmetric the center line because the force forced. Two displacement sensors on sides of tubes detect the force and output electric signals. The signals regulated, mass flow directly produced.

2. Technical Specifications of Products

3.1 Technical Specifications

Table of Technical Specifications (Table 1)

3.2 Other Specifications Environmental Specifications (Table 2)

Specifications (Table 3)

4. Configurations of Products

4.1 Classify of Products

Products specs are divided to eleven based on nominal line sizes: DN1, DN3, DN6, DN10, DN15, DN25, DN40, DN50, DN80, DN100, DN150 (units: mm).

4.2 Configurations

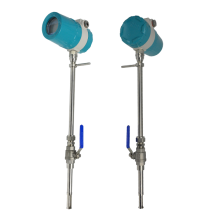

Figure 2 Essential Safety Transmitter Figure 3 Composite Transmitter and Sensor

Every meter consists of two parts: the sensor (primary meter) and the transmitter (secondary meter).

The sensor (primary meter) is machinery part of mass flow meter. There are a vibrator, two displacement sensors and a temperature sensor in it.

The transmitter (secondary meter) is display part of the meter, also is electrical part. There are power supply, analog circuits, digital circuits, displayer, and output circuits and so on in it. Its foundational functions are receiving and regulating the electrical signal from sensors, directly getting mass flow, temperature and density after regulating, and calculating volume flow and other need parameters from known parameters. It can display, output, store and long distance transmit, and you can modify the parameters of flow meter. There is a diode safety barrier in transmitters; the function of the diode safety barrier is safeguard to isolating explosion.

As the composite explosion-proof flow meter, the sensor (primary meter) is essential safety; the transmitter (secondary meter) is explosion isolated. The sensor and the transmitter may all operate under hazardous area.

As the essential safety flow meter, the sensor (primary meter) can operate under hazardous area, the transmitter (secondary meter) must only operate under prescriptive safety area (see section 3.2), forbidden to operate under hazardous area.

Contact us if you need more details on Flow Meter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flowmeter、Flow Meters. If these products fail to match your need, please contact us and we would like to provide relevant information.

Mass flow+ volume flow+density +temperature measurement+calculated variables (e.g. fluid concentrations)

I. Main technical parameters

(1) Measurement scope: 2kg/h~500t/h

(2) Accuracy: ± 0.2%~± 0.15%

(3) Work pressure: (0~32) MPa (in case of other high pressure, it must be of special order)

(4) Medium temperature: -50º C~ +350º C,

Measurement accuracy: ± 1º C

(5) Environment temperature: -20º C ~ +70º C

(6) Measurement medium: Liquid, gas, solid, or two phases and three phases mixed fluid

(7) Output signal:

4-20mA current signal of flow, with load resistance ≤ 500Ω

0-10kHz frequency signal of flow.

RS485 Communication protocol

Hart protocol

(8) Power supply voltage: 24VDC

(9) Measurement of measuring pipe: 316L stainless steel

(10) Response time: 0.1s~5s, adjustable

(11) Explosion-proof grade: Ex(ib)II BT2-T5

Mass flow sensor

Composite type mass flowmeter- all - in- one type

Structure:

Every meter consists of two parts: the sensor (primary meter) and the transmitter (secondary meter). The sensor (primary meter) is machinery part of mass flow meter. There are a vibrator, two displacement sensors and a temperature sensor in it.

The transmitter (secondary meter) is display part of the meter, also is electrical part. There are power supply, analog circuits, digital circuits, displayer, and output circuits and so on in it. Its foundational functions are receiving and regulating the electrical signal from sensors, directly getting mass flow, temperature and density after regulating, and calculating volume flow and other need parameters from known parameters. It can display, output, store and long distance transmit, and you can modify the parameters of Flow Meter. There is a diode safety barrier in transmitters; the function of the diode safety barrier is safeguard to isolating explosion.

As the composite explosion-proof flow meter, the sensor (primary meter) is essential safety; the transmitter (secondary meter) is explosion isolated. The sensor and the transmitter may all operate under hazardous area.

As the essential safety flow meter, the sensor (primary meter) can operate under hazardous area, the transmitter (secondary meter) must only operate under prescriptive safety area (see section 3.2), forbidden to operate under hazardous area.

The sensor can be installed vertically or horizontally.

1. Introduction of Coriolis flow meter

The Coriolis force mass flowmeter can measure the mass flow rate directly, and won't be affected by the measured medium temperature, pressure, density, viscosity.

High precision of CMF series of Coriolis force mass flowmeter is mainly used to measure the instantaneous mass flow rate and cumulative mass flow, instantaneous volume flow and cumulative volume flow, at the same time also can display the medium temperature, medium density or concentration. It is mainly suitable for the following industries:

(1) he Toil industry, such as diesel, gasoline, heavy oil fuel metering; Crude oil output measurement, moisture content, the single well production; Crude oil loading and unloading metering, etc.;

(2) The chemical industry, such as toluene, xylene, butanone, cyclohexanone, n-butyl alcohol, isobutyl alcohol, methylene chloride, chloroform, liquid sulfur, lactam etc;

(3) The power industry, such as heavy oil, diesel fuel oil metering, slurry density meter limestone-gypsum wet desulphurization;

(4) The food, pharmaceutical industries, such as chocolate syrup, milk, fruit juice, pharmaceuticals, BPC (bulk pharmaceutical chemicals) measurement (clamp type healthy connection type);

(5) The energy industry, such as liquefied petroleum gas, natural gas, high pressure gas metering;

Introduction Coriolis Mass Flow Meters patented and developed by our company are the leading meters for precision flow measurement. And with good reason, the meters offer the most accurate measurement available for virtually any process fluid, while exhibiting exceptionally low pressure drop. The meters offer direct mass flow, volume flow, density, and temperature measurement of liquids and slurries - without the need for additional equipment, manual calculations, or estimations.

The meters are designed for unsurpassed performance in even the harshest operating environments. They have no moving parts, and any special mounting or flow conditioning requirements. Every meter is available with stainless steel wetted parts and a wide variety of process connections to meet your every need.

The meters carry hazardous area approval for P. R. China.

1. Principles of Measurement

The structure of Coriolis Mass Flow Meters was consisted of a pair of bended tubes. The principle is to detect Coriolis force forced a pair of tubes from inner mass flow by fluid.

A new force-Coriolis force would be appear while two conditions met: (1) vibrating with normal frequency in a pair of bended tubes, (2) fluid flowing in tubes. This force was produced upon synthesis from vibrating force and flowing force by fluid in tubes. And tubes would be wresting symmetric the center line because the force forced. Two displacement sensors on sides of tubes detect the force and output electric signals. The signals regulated, mass flow directly produced.

2. Technical Specifications of Products

3.1 Technical Specifications

Table of Technical Specifications (Table 1)

| Titles | Technical Specifications |

| Mass flow accuracy | ±[0.2% +(zero stability /flow rate×100%)] |

| Mass flow repeatability | ±(1/2) ×[0.2% +(zero stability /flow rate×100%)] |

| Density range | 0.2 g/cm3~3.5g/cm3 |

| Density accuracy | ±0.002g/cm3 |

| Temperature range | -60º C~+200º C |

| Temperature accuracy | ±1º C |

| Output of current loop | 4mA~20mA |

| Output of frequency/pulse | 0Hz~10kHz |

| Contactor capacity of a Batch Control relay | 24V/0.1A |

| Contactor form | normal open |

3.2 Other Specifications Environmental Specifications (Table 2)

| Titles | Specifications |

| Temperature range of fluid | -40º C~+200º C |

| Environmental temperature range | 0º C~+40º C |

| Environmental humidity | ≤90% RH, non condensation |

| Atmospheric pressure range | 86kPa~106kPa |

| Power supply of transmitters | DC (24±10%) V |

| Power consumed | <15W |

| Specs | Line Sizes (mm) | Flow Range (t/h) | Calibration Range (t/h) | Max. Tube Pressure (MPa) | Zero Stability (t/hr) | Velocity Parameter (h m/t s) |

| DN1 | 1 | 0~0.04 | 0.004~0.04 | 30.0 | 0.000008 | 353.7 |

| DN3 | 3 | 0~0.35 | 0.035~0.35 | 30.0 | 0.000067 | 39.3 |

| DN6 | 6 | 0~0.7 | 0.07~0.7 | 30.0 | 0.00016 | 19.65 |

| DN10 | 10 | 0~1.2 | 0.12~1.2 | 30.0 | 0.0002 | 4.912 |

| DN15 | 15 | 0~6.4 | 0.64~6.4 | 4.0 | 0.0011 | 2.183 |

| DN25 | 25 | 0~16 | 1.6~16 | 4.0 | 0.002 | 0.902 |

| DN40 | 40 | 0~40 | 4~40 | 4.0 | 0.003 | 0.334 |

| DN50 | 50 | 0~65 | 6.5~65 | 4.0 | 0.006 | 0.197 |

| DN80 | 80 | 0~160 | 16~160 | 2.5 | 0.01 | 0.0873 |

| DN100 | 100 | 0~250 | 25~250 | 2.5 | 0.015 | 0.0544 |

| DN150 | 150 | 0~550 | 55~550 | 2.5 | 0.03 | 0.0239 |

4. Configurations of Products

4.1 Classify of Products

Products specs are divided to eleven based on nominal line sizes: DN1, DN3, DN6, DN10, DN15, DN25, DN40, DN50, DN80, DN100, DN150 (units: mm).

4.2 Configurations

Figure 2 Essential Safety Transmitter Figure 3 Composite Transmitter and Sensor

Every meter consists of two parts: the sensor (primary meter) and the transmitter (secondary meter).

The sensor (primary meter) is machinery part of mass flow meter. There are a vibrator, two displacement sensors and a temperature sensor in it.

The transmitter (secondary meter) is display part of the meter, also is electrical part. There are power supply, analog circuits, digital circuits, displayer, and output circuits and so on in it. Its foundational functions are receiving and regulating the electrical signal from sensors, directly getting mass flow, temperature and density after regulating, and calculating volume flow and other need parameters from known parameters. It can display, output, store and long distance transmit, and you can modify the parameters of flow meter. There is a diode safety barrier in transmitters; the function of the diode safety barrier is safeguard to isolating explosion.

As the composite explosion-proof flow meter, the sensor (primary meter) is essential safety; the transmitter (secondary meter) is explosion isolated. The sensor and the transmitter may all operate under hazardous area.

As the essential safety flow meter, the sensor (primary meter) can operate under hazardous area, the transmitter (secondary meter) must only operate under prescriptive safety area (see section 3.2), forbidden to operate under hazardous area.

Contact us if you need more details on Flow Meter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flowmeter、Flow Meters. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : mass flowmeter

Premium Related Products

Other Products

Hot Products

High pressure natural gas instrument air manifoldStainless steel industrial 3-way valve manifoldFloat angle double block and bleed plug valve3 way lockable forged ball valvestainless steel three way port ball valveThreaded stainless steel cross ball valvesStainless high pressure air precision needle valveTube compression fittings angle air operate needle valvecf8m stainless steel female male automatic ball valve.JW-LOK Hamlet instrument ball valveStainless steel multi port gauge valveHigh pressure 2 way valve manifoldHigh pressure 6000psig bar stock ball valveSpeedy Trunnion Mounted Ball Valve for natural gasMost selling products of radiator auto air vent valveHigh quality Forged steel piston globe valve